Quote:

Originally Posted by kalan850

Looking good. I subd. Your filtration setup is unique. Care to elaborate on it?

Sent from my SM-G900V using Tapatalk

|

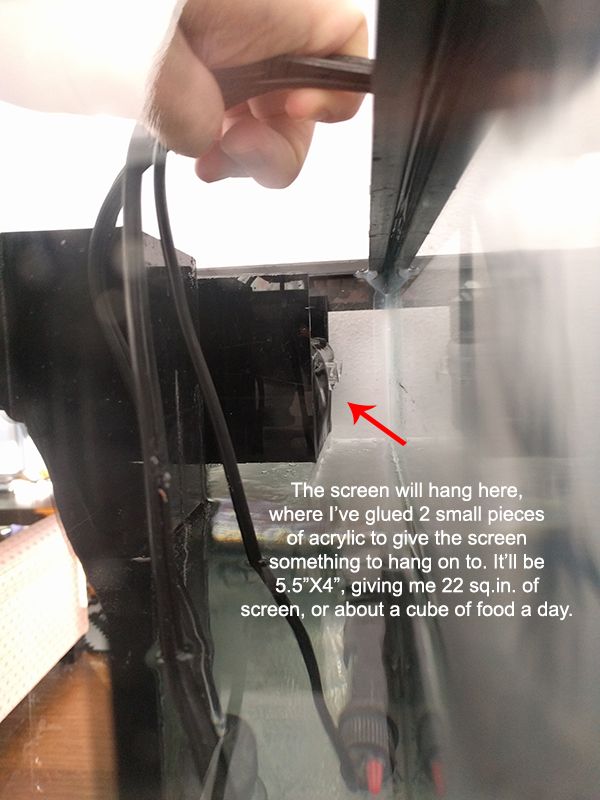

Sure! My nutrient export will revolve around an overflow style Algae Turf Scrubber. I refuse to listen to an air pump 24/7, so I won't be using an upflow ATS. I created a little acrylic box that hangs on the back of the overflow which will provide a little mechanical filtration. The water will exit this box and flow down my scrubber screen and into the rest of the sump area. I will have my DIY LED fixture on the outside of the tank lighting up the screen. The rest of the sump below the box is completely open where I can put a heater, bag of carbon, ATO sensor, and the pump.

In the photo I'm just giving an example of how much I might need to feed the tank if it's totally stocked with fish and corals. I don't know if I'll ever need a cube a day, but I wanted the sump to be open so I could make the scrubber as long as it needed to be.

Quote:

Originally Posted by Devaji108

nice job sir!

I am very interested with measurements too if possible.

I thought silicone & acrylic did not bond very well?

|

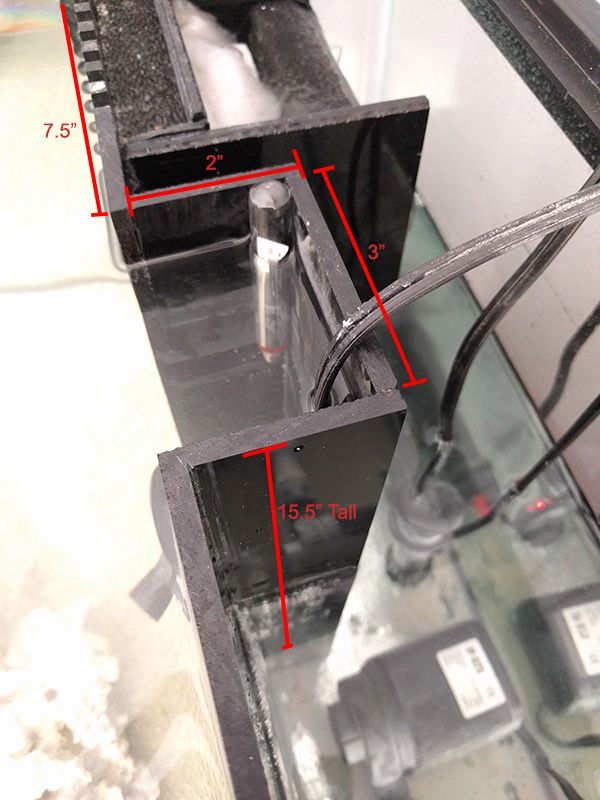

You're right, silicone doesn't bond well with acrylic. I used Weldon 4 and Weldon 16 to attach the pieces together once I had them cut out. The inside of a 40 Breeder is 17.5 inches, so that's what I started with. I wanted a 3 inch notch in the middle of the false wall so I could hide a wave maker pump, so I cut (2) 7.5" pieces and (1) 3" piece (7.5+7.5+3=17.5"). I made the notch 2" deep, and my acrylic is 1/4" thick, so I cut (2) 1 3/4" pieces to hold the 3" piece.

I bought a 24"X24"X1/4" piece of black acrylic for about $42 online from USPlastic. This is plenty of material to work with. If you're going to cut the acrylic yourself, don't forget to account for the 1/8" saw blade of your table saw. I cut (10) 1.5" deep teeth and they have no problem handling the water flow from my ~400GPH pump. They could easily hand triple that, yet the waterline is still hidden above the black rim of the tank with a 15.5" tall wall. When gluing the pieces together, pay attention to where I have them placed. The 3" piece needs to go

inside the two 2" pieces.