|

|

|

|

#26 |

|

Skimmer Guy

Join Date: Apr 2007

Location: IN

Posts: 5,647

|

well the cylinder is cell cast. the only extruded piece I have right now is the bubble plate pieces.

__________________

Mojo~ |

|

|

|

|

#27 |

|

Moved On

Join Date: Oct 2008

Location: here.

Posts: 2,509

|

No biggie then....it does get kinda tricky welding cast to extruded and making it pretty...extruded is fine for your project, strength wise, it just sucks to machine and glue/weld...

|

|

|

|

|

#28 |

|

Skimmer Guy

Join Date: Apr 2007

Location: IN

Posts: 5,647

|

thanks for the input. I am still not sure how I am going to attatch the pvc to the acrylic though. Any thoughts on this? As far as I see it, I can glue or weld it. Nit sure what glue to use. Weld on. I am going to play around on scrap first.

__________________

Mojo~ |

|

|

|

|

#29 |

|

Registered Member

Join Date: Feb 2008

Location: Harlan, IN

Posts: 92

|

Looking good! definitly wanna see these things run

__________________

what up! Current Tank Info: 75 gallon & 26 bow |

|

|

|

|

#30 |

|

Registered Member

Join Date: Nov 2005

Location: queens n.y

Posts: 2,209

|

you can use both : Weld On 16 Or 40 2 part.

|

|

|

|

|

#31 |

|

Skimmer Guy

Join Date: Apr 2007

Location: IN

Posts: 5,647

|

I was going to use weld on 16 for most and 3 for Bubble plate items.

__________________

Mojo~ |

|

|

|

|

#32 |

|

Moved On

Join Date: Oct 2008

Location: here.

Posts: 2,509

|

+1 weldon 16. Or 40 prefereably the 40thou....

|

|

|

|

|

#33 |

|

Registered Member

Join Date: Nov 2003

Location: Charlotte, NC

Posts: 49

|

I use WO 40 for pvc to acrylic. If you have the money get the 42, it is the same but it self mixes with the $300 static mixing gun.

|

|

|

|

|

#34 |

|

Skimmer Guy

Join Date: Apr 2007

Location: IN

Posts: 5,647

|

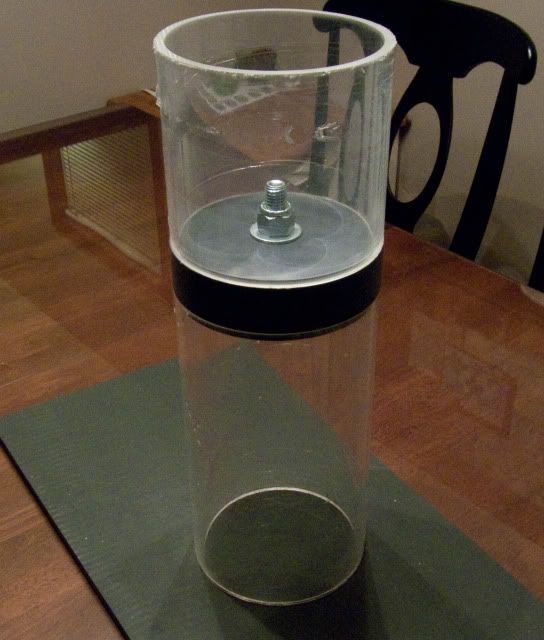

Well here is phase one of the cylinder skimmer.

__________________

Mojo~ |

|

|

|

|

#35 |

|

Registered Member

Join Date: May 2001

Location: Indianapolis, IN / Muncie, IN

Posts: 8,219

|

Get that neck on a lathe, let's go!

|

|

|

|

|

#36 |

|

Registered Member

Join Date: Nov 2006

Location: Ft. Wayne, IN

Posts: 2,967

|

Can't wait to see this thing in person.

__________________

Proud member of FWMAS. Current Tank Info: Empty 75g sitting in the garage. Needs to be up and running |

|

|

|

|

#37 |

|

Skimmer Guy

Join Date: Apr 2007

Location: IN

Posts: 5,647

|

lol I did have it on the lathe to mill down the outside. Waiting on the neck piece so I have the exact OD to mill the ID on the neck. hopefully will be able to do more tomorrow. Been busy today.

__________________

Mojo~ |

|

|

|

|

#38 |

|

Registered Member

Join Date: Apr 2005

Location: Greenville, SC

Posts: 9,687

|

Very interested to see how you do the neck.

Personally having used 16 and 40 before, there's no way I would use 16. 40, although slightly more of a pain to deal with, is a much better product especially when gluing pvc and acrylic pieces together. I used about 1/2 cup of 40 this week on various projects

__________________

-Eric- |

|

|

|

|

#39 |

|

Skimmer Guy

Join Date: Apr 2007

Location: IN

Posts: 5,647

|

thanks for the input everyone. I still havent gotten the pieces for the neck. Once I get them I can machine out the neck.

The neck is pretty heavy. And it added a extra cost to my build. I Went to take it of my table and it slipped out of my hand. Caught the edge of the protective glass and broke it. The neck is still in one piece but their is another $90 to replace the glass on the table. lol. I am also throwing around the ideas for the base of the skimmer. I can just put a plate on the bottom or make a small box that would help make the skimmer a little taller. One thing at a time. I didnt really plan on putting a ton of air into this one. somewhere between 700 and 900 lph. I will probably try it out the way it is first and just pres fit it together and go from there.

__________________

Mojo~ |

|

|

|

|

#40 |

|

Skimmer Guy

Join Date: Apr 2007

Location: IN

Posts: 5,647

|

OK OK a couple pics to show progess on the neck. I did get my Cone body in yesterday as well. Thanks Victor (ATB) for that. I had to twist his arm but my cone skimmer will have a ATB 840 1.5 body. woot.

Ok back to my cylinder skimmer.

__________________

Mojo~ |

|

|

|

|

#41 |

|

Moved On

Join Date: Oct 2008

Location: Utah

Posts: 138

|

Thats looking pretty good.

|

|

|

|

|

#42 |

|

Skimmer Guy

Join Date: Apr 2007

Location: IN

Posts: 5,647

|

hanks I am actually pretty happy with it so far.

__________________

Mojo~ |

|

|

|

|

#43 |

|

Skimmer Guy

Join Date: Apr 2007

Location: IN

Posts: 5,647

|

well here is the new bubble plate I have made Took the advice and put in more holes and a little larger diameter.

Bubble plate is 1/2 thick acrylic.

__________________

Mojo~ |

|

|

|

|

#44 |

|

Registered Member

Join Date: Jul 2003

Location: san jose ca

Posts: 1,303

|

Looks good especially for a manual machine

|

|

|

|

|

#45 |

|

Skimmer Guy

Join Date: Apr 2007

Location: IN

Posts: 5,647

|

yea for doing everything manual I dont think its coming along too bad.

Thanks Victor

__________________

Mojo~ |

|

|

|

|

#46 |

|

Registered Member

Join Date: Feb 2009

Location: Greensboro, NC

Posts: 766

|

What type of pump will you be using on the cylinder one? Tunze?

-Dave

__________________

Dave Current Tank Info: 35g Shallow Reef Build/iTech 100/Tunze Osmolator/MP20/Sunpower |

|

|

|

|

#47 |

|

Registered Member

Join Date: Apr 2005

Location: Greenville, SC

Posts: 9,687

|

It's hard to gauge the size of the holes, but are you sure there are enough? Most normal bubble plates have more holes than acrylic, and yours is the opposite. I just don't want to see you having to redo the plate later after it's assembled because it's heavily restricting flow.

__________________

-Eric- |

|

|

|

|

#48 |

|

Skimmer Guy

Join Date: Apr 2007

Location: IN

Posts: 5,647

|

The are 1/4" so they are actually pretty good size. and there are 41 holes. I have more disks cut so I can make more if I need to.

This skimmer will run a sicce motor block with a custom volute. IT should be a really nice sicce pump. Non directional volute, new reducer from marinesolutions. We will see.

__________________

Mojo~ |

|

|

|

|

#49 |

|

Registered Member

Join Date: Apr 2005

Location: Greenville, SC

Posts: 9,687

|

Cool. If you can swap it out easily after it's running (just in case), even better

__________________

-Eric- |

|

|

|

|

#50 |

|

Skimmer Guy

Join Date: Apr 2007

Location: IN

Posts: 5,647

|

The plate is 4 in round as well. I will actually check it with out a plate and then with. I did order some weldon #40 to glue the acrylic to the pvc.

__________________

Mojo~ |

|

|

|

|

|