|

|

|

|

#301 |

|

Registered Member

Join Date: Dec 2007

Location: Central California Coast.

Posts: 5,383

|

My stand is a project in itself.

It's for a 280 Tall I'll be building. It's 70 x 24 x 36T. It's not the box structures we're seeing here. My stand needs to raise and lower while holding 3,000lbs on it. It will only be supported near the four corners. There is no way to center support it. So the top needs to be very rigid. Because of this I'm using 1-1/2" x 3" 0.120" rectangular steel tubing, sort of a two by four made of steel. I cut the tubing today and hope to throw some welds into to it tomorrow(Sat). I haven't got the bill yet but steel is a lot more expensive than it used to be.. They told me they get price increases every 2 weeks. |

|

|

|

|

|

#302 |

|

Registered Member

Join Date: Dec 2007

Location: Central California Coast.

Posts: 5,383

|

Oh hey! You DO need to worry about how close to the edge you cut. I messed with that today. Seems you need to cut near the ends inside from the end at least the width of your cut off saw blade. I was getting serious blade wander when trying to cut closer than that.

|

|

|

|

|

|

#303 | ||

|

Welcome to the next level

Join Date: Aug 2005

Posts: 2,412

|

Quote:

This sounds pretty neat with the whole "raise and lower while holding 3,000 lbs" aspect. I paid $1.71/ft for my 1.5"x1.5" square tubing so Im guessing that your 1.5"x3" tubing is going to run you roughly double that. Id guess its probably in the $3.50-$4 /ft now. Quote:

Looking forward to seeing this steel beast!

__________________

"Never be afraid to do something new. Remember, amateurs built the ark; professionals built the titanic." -Anonymous Current Tank Info: tankless Last edited by MeuserReef; 05/31/2008 at 06:43 AM. |

||

|

|

|

|

|

#304 |

|

Registered Member

Join Date: Jan 2007

Location: DFW

Posts: 207

|

wowser this stuff is sticky and gets everywhere!

|

|

|

|

|

|

#305 | |

|

Welcome to the next level

Join Date: Aug 2005

Posts: 2,412

|

Quote:

Are you going to apply a second coat? If so, I think the instructions say to do it within 12-24 hours after the first. Supposedly this allows the two coats to bond together. Your stand looks very nice with that coating on it. Any ideas as to an outside cabinet?

__________________

"Never be afraid to do something new. Remember, amateurs built the ark; professionals built the titanic." -Anonymous Current Tank Info: tankless |

|

|

|

|

|

|

#306 |

|

Registered Member

Join Date: Dec 2007

Location: Central California Coast.

Posts: 5,383

|

Ah a realll man would've done that in the living room!

LOL Tell us how it works out. |

|

|

|

|

|

#307 |

|

Registered Member

Join Date: May 2008

Location: Chandler, AZ

Posts: 531

|

Out of curiousity - what are people getting quoted for on the steel - I checked out my normal show - and it was $3.80/ft for 1.5 x 1.5 1/8" thick.

|

|

|

|

|

|

#308 | |

|

Registered Member

Join Date: Jan 2007

Location: DFW

Posts: 207

|

Quote:

|

|

|

|

|

|

|

#309 | ||

|

Welcome to the next level

Join Date: Aug 2005

Posts: 2,412

|

Quote:

I purchased my 1.5" x 1.5" (1/8" thick) steel for $1.71 / ft. It was sold to me in (2) 24' sections. I ended up using a total of 44 feet to build a 32" tall stand for a 60"x18" (120 gallon) tank. I would imagine that you would be looking at somewhere in the 50-60 ft range for your 150, depending on the desired height and footprint. I know every market is unique, but $3.80 sounds a bit high to me. I would keep searching. Call around to some of the welding shops in the area and ask them where you should go for your steel. Start with a few of THESE PLACES and if your not satisfied, try a few of THESE PLACES Quote:

__________________

"Never be afraid to do something new. Remember, amateurs built the ark; professionals built the titanic." -Anonymous Current Tank Info: tankless Last edited by MeuserReef; 05/31/2008 at 09:45 PM. |

||

|

|

|

|

|

#310 |

|

Registered Member

Join Date: May 2008

Location: Chandler, AZ

Posts: 531

|

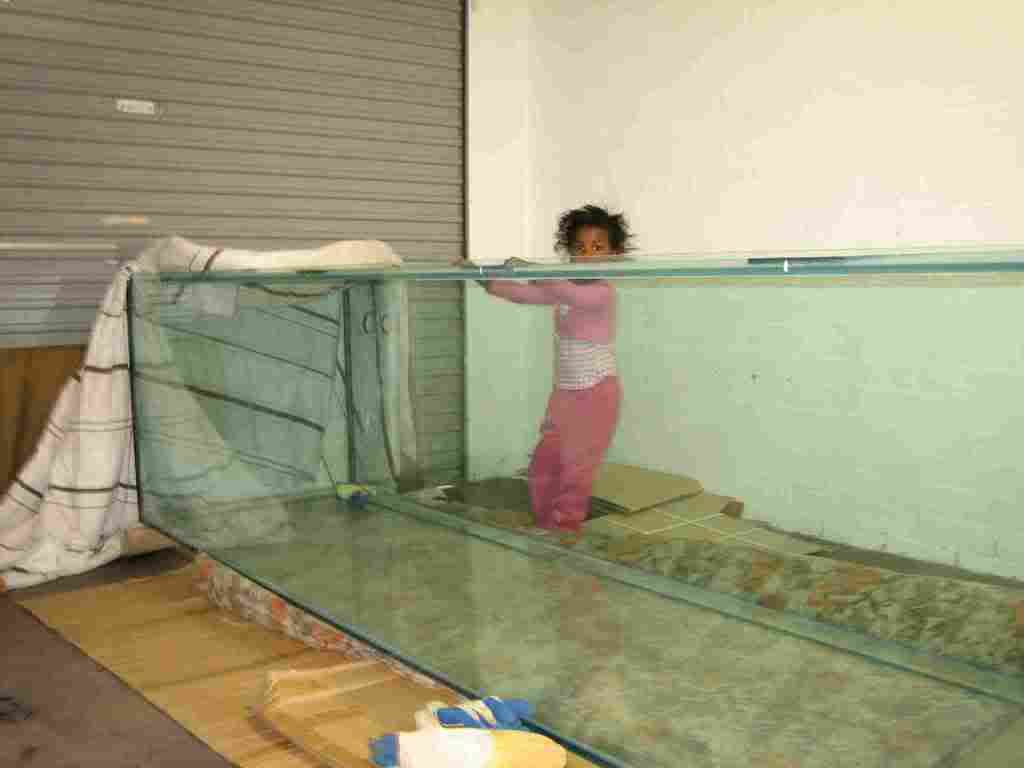

I calculated 50 ft of the 1.5" for my stand. I know prices are going up - but - I don't think they've doubled in 2 months.

There are a couple other places that I've dealt with in the past. Here's my last "welding" project. Last edited by Frank AZ; 05/31/2008 at 10:15 PM. |

|

|

|

|

|

#311 | |

|

Registered Member

Join Date: Dec 2007

Location: Central California Coast.

Posts: 5,383

|

Quote:

That is to the penny what I was quoted for 2x2xsame on Tues. Depends on where you are though - fuel costs could run it up. |

|

|

|

|

|

|

#312 | |

|

Registered Member

Join Date: Jan 2007

Location: DFW

Posts: 207

|

Quote:

|

|

|

|

|

|

|

#313 |

|

Registered Member

Join Date: Dec 2007

Location: Central California Coast.

Posts: 5,383

|

I keep doing battle with Google Sketch I'm not getting to first base with that. Nothing much seems logical.

Anywho. Here's some shots of my "platform". The just cut tubing. The ends ground to bevels. In approximate position for welding. |

|

|

|

|

|

#314 |

|

Registered Member

Join Date: Jan 2007

Location: DFW

Posts: 207

|

|

|

|

|

|

|

#315 |

|

Registered Member

Join Date: Apr 2008

Location: Melbourne

Posts: 14

|

Weeks spent on the NET trying to design a reliable stand for my 12' X 2.5' X 2.5' tank and I stumble upon this thread...literally a DAY after I weld my stand together out of impatience. Ironic. Anyway, after having seen many sturdy stands here and confident posts, I think I MIGHT have to reconsider the design. My tank is 12' X 2.5' X 2.5' and would weigh close to 2.5 tonnes once filled. I have used 50mm X 50mm X 4mm Gal RHS tubing throught the entire stand. Below are some pics:

The tank for starters:   The stand:    The stand - bottoms-up:  Does any of you think I need: 1. More cross braces on top? 2. Should I use diagonal supports too? Your help is HIGHLY appreciated. Thanks again ya'll. Neo.

__________________

SLOWLY BUILDING MY 12' X 2.5' X 2.5' FOWLR tank Current Tank Info: 12' X 2.5' X 2.5' |

|

|

|

|

|

#316 |

|

Registered Member

Join Date: Sep 2005

Location: Hollywood Florida

Posts: 3,633

|

.

Thats overkill already. That looks alot like my stand for my 120x36x30 tank    There is no way it needs more. Mine needed 4 guys to move and i was able to sleep knowing that it was totally overbuilt . |

|

|

|

|

|

#317 |

|

Reef Hugger

Join Date: Jul 2007

Location: Submerged

Posts: 3,253

|

nyvp - wicked stand! what material did you use for the top and trim?

__________________

-Austin Make your animals Thrive, not just Survive. |

|

|

|

|

|

#318 | |

|

Registered Member

Join Date: Dec 2007

Location: Central California Coast.

Posts: 5,383

|

Quote:

You do need some cross bracing though. You can do exactly what 20vturbo did. Or in lew of the gussets put a few front to back braces whichever. nyvp; You are treading on thin ice with no rack bracing at all. I would be figuring how to add some somehow. Wood siding or two pieces of strap iron bolted across the long plane. BTW that is a gorgeous sea scape you have going there. Very nice. 20vturbo; Thanks for the google link I will check it out! |

|

|

|

|

|

|

#319 | |

|

Moved On

Join Date: Dec 2004

Location: Elk Grove

Posts: 677

|

Quote:

Last edited by TeeLapia; 06/04/2008 at 04:03 PM. |

|

|

|

|

|

|

#320 |

|

Moved On

Join Date: Dec 2004

Location: Elk Grove

Posts: 677

|

OOPPSS... double post. sorry

|

|

|

|

|

|

#321 |

|

Welcome to the next level

Join Date: Aug 2005

Posts: 2,412

|

Holy Cow! I leave for few days and this thread explodes with more awesome stands!

Frank AZ.. did you build that thing to contact the mother ship or what? What is it? Antenna? Lightning generator? (excellent welding, regardless of what it is!) kcress.. looking really good! neodama.. simply crazy tank and stand. nyvp.. LOVE the granite! TeeLapia.. got any pics on the way?

__________________

"Never be afraid to do something new. Remember, amateurs built the ark; professionals built the titanic." -Anonymous Current Tank Info: tankless |

|

|

|

|

|

#322 |

|

Registered Member

Join Date: Mar 2004

Location: Enumclaw, WA

Posts: 163

|

Can I join? I designed this in multiple pieces so that I could get it through the door. The stand is 84"x40"x40".

Each section below got tab to hold plywood.  Then lined the bottom with a sheet of 1/4"ABS

|

|

|

|

|

|

#323 |

|

Registered Member

Join Date: Mar 2004

Location: Enumclaw, WA

Posts: 163

|

I then gave the top a hardwood piece of plywood to set the tank on.

Trimmed out the bottom so it matched the floor.  Blue l.e.d. lights below for a cool effect.  The final product with my perimeter shelf and linear actuated canopy that I built. Each section will also get inset frosted glass doors.

|

|

|

|

|

|

#324 | |

|

Welcome to the next level

Join Date: Aug 2005

Posts: 2,412

|

Quote:

(kidding Mods...only kidding! Closing this thread could unwrap the space-time continuum!!). Bricky had to go and post his IMMACULATE stand! (kidding Mods...only kidding! Closing this thread could unwrap the space-time continuum!!). Bricky had to go and post his IMMACULATE stand! I read through (and voted for) your build thread and man.... you have got some serious skills my friend! Great work and thanks for posting your stand in this thread. Im also glad to see that you have your interests in the right order, especially the first 3!

__________________

"Never be afraid to do something new. Remember, amateurs built the ark; professionals built the titanic." -Anonymous Current Tank Info: tankless |

|

|

|

|

|

|

#325 |

|

Registered Member

Join Date: Mar 2004

Location: Enumclaw, WA

Posts: 163

|

Thanks for the kind words and the vote.

|

|

|

|

|

| Thread Tools | |

|

|