|

|

|

|

#1 |

|

Registered Member

Join Date: Jan 2013

Posts: 169

|

Plumbing parts: tapered or not?

I was told the NA standard is tapered threads and local plumbing stores sell such parts.

BRS parts are not tapered. When using such parts it's easier to predict a final size when everything is connected. Does it matter which parts to use? |

|

|

|

|

|

#2 |

|

Man who sold the world

Join Date: Oct 2004

Location: Oakley, behind enemy lines in communist occupied California.

Posts: 254

|

No, it doesn't, so long as they don't leak

Use some teflon tape on threads (sparingly and don't over tighten.

__________________

LED snob. Unapologetic Luxeon Rebel and Bridgelux Vero fanboy. Every time a fluorescent or halide fixture is scrapped, an angel gets its wings. |

|

|

|

|

|

#3 |

|

Registered Member

Join Date: May 2003

Location: Anaheim, CA

Posts: 6,902

|

Threaded PVC should not use teflon tape as your more likly tp split the fittings and not get a leak proof joint. Teflon past is the proper sealer for threaded PVC joints per the manufacturers.

__________________

240G mixed reef, 29G SPS/LPS clam tank, 50G mixed reef Current Tank Info: 300g mixed reef, 50g cube |

|

|

|

|

|

#4 |

|

Registered Member

Join Date: Jun 2009

Location: Fort Collins,CO

Posts: 426

|

Exactly what Laverda said

|

|

|

|

|

|

#5 | |

|

Registered Member

Join Date: Apr 2013

Posts: 1,793

|

Quote:

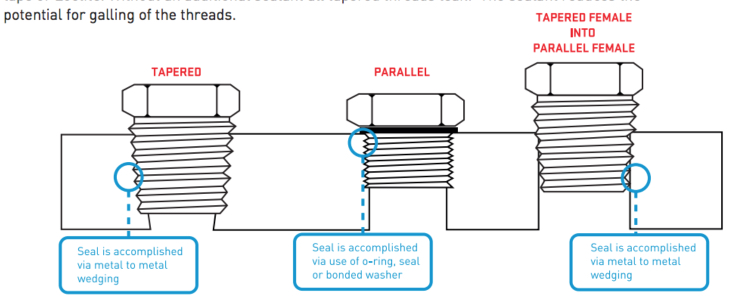

Tapered threads are used internationally.. well UK and the US for sure. NPT BSPT Boring article on thread type and ID: https://trimantec.com/thread-identification-guide/ The purpose was to get a metal to metal seal. Technically no "sealant" was needed. Sloppy manuf of threads and assembly have created the need for a bit more. Also helps in dis-assembly.. Straight threads are usually accompanied by an o ring or some sort of gasket. Sealing straight threads w/ tape/dope is not recommended. https://www.homedepot.com/p/RectorSe...3631/100201204 "Teflon" tape was developed as a lubricant and aid in disassembly. Not a sealant.. though I guess in a sense it has exceeded its expectations.. https://www.plantengineering.com/art...hread-sealant/ |

|

|

|

|

|

|

#6 |

|

Registered Member

Join Date: May 2003

Location: Anaheim, CA

Posts: 6,902

|

Electrical fittings have straight threads and as stated above use an o-ring. The threads have the same pitch and nominal so they will screw together.

__________________

240G mixed reef, 29G SPS/LPS clam tank, 50G mixed reef Current Tank Info: 300g mixed reef, 50g cube |

|

|

|

|

|

#7 |

|

Registered Member

Join Date: Jan 2013

Posts: 169

|

Well, after several calls to BRS I realized they don't know for sure if the threads are tapered or straight (unless it's directly mentioned in the description on the site).

From Understanding NPT, NPTF & NPS Thread Connections NPS = National Pipe Straight NPT = National Pipe Thread NPTF = Nation Pipe Thread Fuel Both NPT and NPS have the same thread angle, shape, and pitch (threads per inch). However, NPT threads are tapered and NPS threads are straight (parallel). Both threads have a 60° included angle and have flat peaks and valleys. Tapered Pipe Thread is commonly found on ends of pipe, nipples and fittings (ex: couplings, elbows, tees, etc.). Sharply angled threads are very critical to joint being tight with no leaks. Thread sealant or tape is typically required to complete the seal. Straight Pipe Threads need a gasket or O-ring to create a seal. While NPT and NPS threads will engage, they do not seal properly with each other. |

|

|

|

|

|

#8 | ||||

|

Registered Member

Join Date: Apr 2013

Posts: 1,793

|

Quote:

Quote:

https://en.wikipedia.org/wiki/National_pipe_thread If you ever disassembled the CGA side of gas regulators you will find most use nothing to seal the NPT threads..Metal to metal. That said, it is sort of arguable both ways. I use pipe dope on all NPT threads.. mostly because of cheap Chinese cutting and being an amateur.. Quote:

anyways measure the diameter on the front and the back of the threaded part.. It's complicated though.. https://www.cpcworldwide.com/Downloads/NPT.pdf Quote:

Last edited by oreo57; 03/02/2019 at 01:47 PM. |

||||

|

|

|

|

|

#9 | |

|

Registered Member

Join Date: Jan 2013

Posts: 169

|

Quote:

|

|

|

|

|

|

|

|